Typically, customers who want to customize glow in the dark masterbatch have the following three requirements:

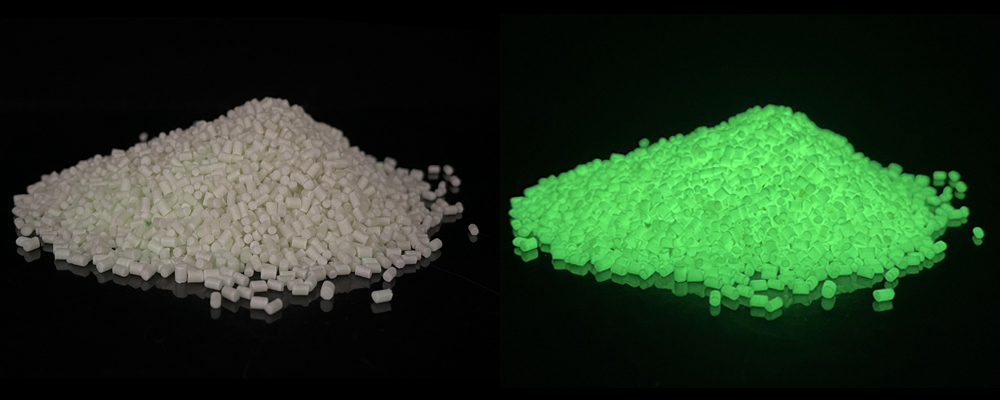

- Accurate daytime color: Customers have specific color codes or customization requests for the product’s daytime color and expect the final product to accurately display their desired color. Customers often provide PANTONE or RAL codes or finished products as reference standards.

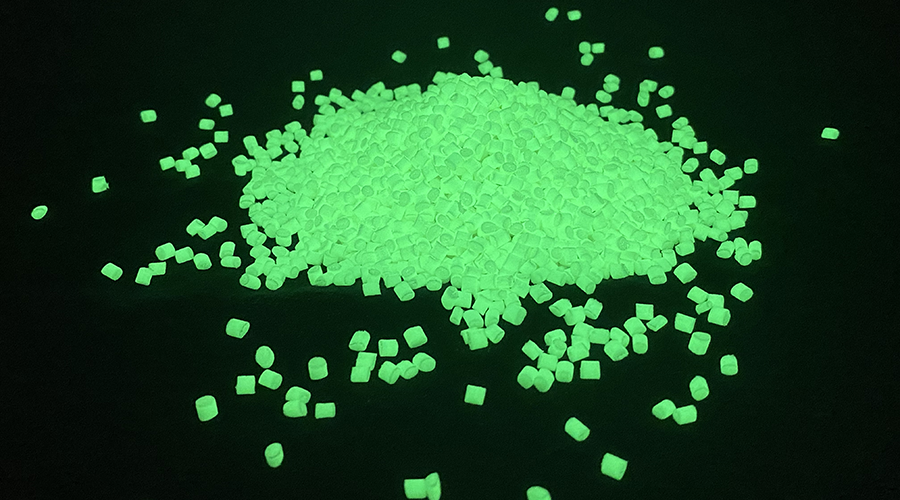

- Good glow in the dark effect: Customers want the product to exhibit a glow in the dark effect in the dark environments.

- Additional performance requirements: Besides above, customers may have other performance requirements for the end product, such as flame resistance, weather resistance, or compliance with certain food-grade standards.

When customizing glow in the dark masterbatch, we consider these requirements comprehensively to ensure that the final product meets the customer’s expectations in all aspects.

To help customers achieve the desired product results, we outline the key steps involved in customizing glow in the dark masterbatch:

Step 1: Material and application confirmation

We need to know the plastic material and application. Additionally, the requirements for the product’s color and glow effect must be clarified. To customize more efficiently and accurately, it is usually necessary for customers to provide samples to establish precise color and brightness

standards.

Step 2: Production of color plates to simulate the final product’s effect

Based on the information mentioned in step 1, we create color plates to simulate the color and brightness effect of the final product. Customers evaluate and confirm the plates. If satisfied, we will proceed with the production of the masterbatch accordingly. If not satisfied, further

adjustments will be made.

Step 3: Production of sample masterbatch

After confirming the color plate in step 2, we will proceed to make sample masterbatch and send it to customer for testing.

Step 4: Customer approval of sample masterbatch

Along with the sample masterbatch, we will provide a recommended dilution ratio. Customers dilute the sample accordingly and compare it against the previously confirmed color plate.

Step 5: Mass production and ongoing support

Once the sample masterbatch gets final approval, we will start mass production .

In conclusion, key points of customizing glow-in-the-dark masterbatch include confirming material, application, color standards, brightness standards etc. This ensures that the final glow-in-the-dark masterbatch perfectly aligns with the customer’s expectations. We will also provide the necessary technical support accordingly. Our team maintains close collaboration with the customer to ensure quality control throughout the production process and consistency in

the final product.

Only through seamless cooperation, can we provide customers with high-quality glow-in-the-dark masterbatch and create stunning effects.

You Might Also Like